Composite Resources

Composite Products

Since our beginning in December 1992, Composite Resources has become a recognized industry leader in the design, prototyping and manufacture of composites. The design and prototyping of composites are two key aspects of our comprehensive in-house composite capabilities.

Composites are a three dimensional combination of a minimum of two materials that differ in composition or form, with a distinct interface that separates the two component materials. Many composite materials are manmade and have been created to attain attributes that cannot be realized by the individual component materials. Many materials are used in the design and prototyping of composite products, such as:

- Carbon Fiber Epoxy

- Styrofoam

- Acrylic

- Kevlar® Epoxy

- Titanium

- Foam

- E-Glass Epoxy

- Polycarbonate

- Stainless Steel

- Velcro

- Honeycomb

- Aluminum (such as 6061-T6)

- Balsa

- Fiberglass

This is just a partial list of the composite materials that Composite Resources has successfully worked with.

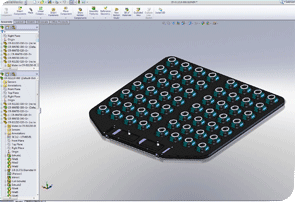

With extensive design experience and the tools to take your design concept from an idea to production, Composite Resources has the knowledge and expertise to recommend the optimum materials for your composite design. Composite Resources' experienced staff has a wide range of design capabilities and tools to successfully develop your product concept, including:

- Concept Design

- Part Rendering

- Pattern Design

- Mold Design

- Reverse Engineering

- Product Design

- 3D Modeling

- Structural Analysis

- Tooling Design

The engineering staff at Composite Resources utilizes a number of software programs to design your composite component, including Solidworks, AutoCAD, Cosmos FEA, CompPRO, GC Place, Corel Draw, and Adobe Illustrator, as well as others. Composite Resources has designed composite products for numerous industries, including the thermoforming, semiconductor, medical, aerospace and automotive sectors. Components that have been developed at Composite Resources include filtration systems, low inertia composite retrievers, race car wings, and rifle hand guards to name a few.

Once the design is finalized, Composite Resources can create a prototype of the component using any of the following methods:

- Laser Cutting

- Stereolithography - rapid prototyping method, with a high degree of accuracy

- Gantry Milling

- Model Making

- Hand Lay Up - open mold process, used for prototyping parts of any dimensions

- CNC Machining

Composite Resources has supplied prototypes for a broad variety of industries from aerospace to recreational. Some prototype examples include aircraft seats and other aircraft components, medical tourniquets, skateboard decks, luggage and croquet mallets.

From the initial concept, to design and prototyping, Composite Resources is your one-stop shop for all your composites needs. We can meet and exceed every specification of your composite component – contact the team at Composite Resources with your composite requirements!

3D model or maybe a hand calculation. We keep it simple. It’s about your needs. All we ask is that you tell us about your project.

Click here for more Product Details from

Composite Resources...