Contact Details:

Dometrics, Inc.

89 Clyde Downs Rd.

Franklin

NC

28734

United States of America

Tel: +1 800 553-2531

Fax: +1 828 369-5418

Send Enquiry | Company Information

Energy efficiency of Elektror devices

Company News Wednesday, August 10, 2011: Dometrics, Inc.

Economical motors are only part of our total concept

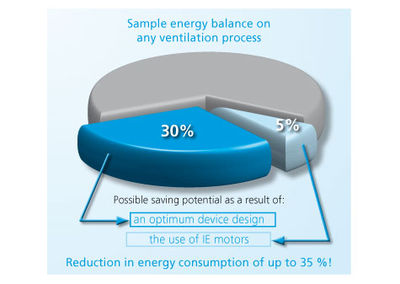

Energy efficiency is a topic that is associated with mechanical and plant engineering at present especially due to the new IEC 60034-30-2008 standard. And this is certainly not without good reason. If you consider that a large percentage of the electric motors used worldwide are affected by this statutory guideline, it is obvious that an enormous energy-saving potential has been identified in global terms. After all, energy savings of 2-5 % per motor will be achieved through these measures. However, our years of experience as a manufacturer of industrial blowers and as a systems supplier indicate that there is potential to make even greater savings.

Experience has made us good

The comprehensive and qualified advice that we provide is the basis of our total concept for energy-efficient blowers and side channel blowers. Optimum efficiency can only ever be achieved when a blower, system and existing basic conditions are in tune with each other. As a result, we are on hand during and after the delivery of your Elektror device to offer you help and advice.

How to achieve optimum energy efficiency

We develop a design for your device together with you that promises maximum efficiency.

Determining the basic conditions and customer requirements

We require a clear picture of your application in order to be able to take into consideration all the relevant points regarding the design of your Elektror device. We are happy to visit your premises for this and to determine fluidic conditions and requirements with mobile measuring equipment.

Selection of the correct Elektror device

In addition to any other device adjustments, it is vitally important that the basic model that is selected can fulfil the requirements. Any over and under sizing must be excluded at this point so that the energy balance is not influenced in a negative way.

Modifications, adjustments and additions

Whether its accessories, standard adjustments or even design modifications, we „file away" at the basic model that is selected until it is optimally adapted to your individual requirements. In so doing, we give all blower components (impeller, housing, motor) a vital check with regard to your application.

The appropriate method for controlling and regulating

Until now the required operating point is set mechanically on many systems, which results in high losses because of the constant blower speed. Blowers that can be adjusted via frequency converters provide significant advantages here because the infinitely variable speed controller ensures that only the pressure and flow rate that is required for the process is produced.

Furthermore, process-oriented, sensor-driven controls can be achieved using frequency converters. The speed of the blower is automatically regulated to the required operating point with this version. This is particularly useful in applications where there are changing conditions on the system in terms of ventilation.

Frequency converter technology is also used these days as an energy-efficient alternative to a belt drive in order to achieve high speeds and, consequently, higher pressures and flow rates. Friction losses of 2-3 % can also be saved on top of the overall lower operating and maintenance costs as a result of a drive belt wearing part not being used.

Energy-efficient motors

Elektror devices (for delivery within Europe) will be fitted with IE2 motors by 16.6.2011 at the latest in accordance with the statutory regulations. You will also obtain motors from us with even better levels of efficiency.

The environment

Even with blowers or side channel blowers with an optimum design, the performance capability can be drastically reduced as a result of faults relating to the electrical or mechanical connection. Designs can also be found within lots of ductwork that can lead to an undesired loss of efficiency and, consequently, to an energy-guzzling high-load operation. Our experts can recognise these faults at a glance and provide you with appropriate proposals for a solution.